Buzzer BP1109S

1. Technical Parameter

Measuring condition

Part shall be measured under a condition (Temperature: 5~35℃, Humidity: 45% ~ 85%R.H., Atmospheric pressure: 860 ~ 1060hPa) unless the standard condition (Temperature: 25±3℃, Humidity: 60±10%R.H. Atmospheric pressure: 860 ~1060hPa) is regulated to measure.

| 1 | Resonant Frequency | 4100Hz |

| 2 | Operating Voltage | 1~20 Vp-p |

| 3 | Rated Current | Max.3mA ,at 4.1KHz 50% duty Square Wave 3Vp-p |

| Max.5mA ,at 4.1KHz 50% duty Square Wave 5Vp-p | ||

| 4 | Sound Output at 10cm | Min 65dB,at 4.1KHz 50% duty Square Wave 3Vp-p |

| Min 70dB,at 4.1KHz 50% duty Square Wave 5Vp-p | ||

| 5 | Capacitance | 12000±30%pF at 1KHz |

| 6 | Operating Temperature | -30℃~+70℃ |

| 7 | Store Temperature | -40℃~+85℃ |

| 8 | Net Weight | Approx 0.2g |

| 9 | RoHS | Yes |

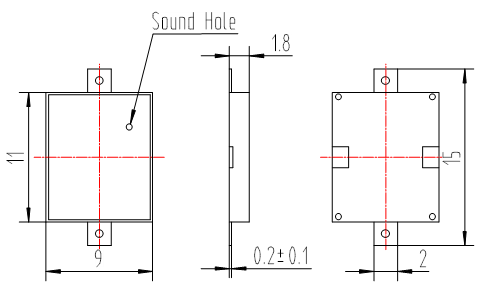

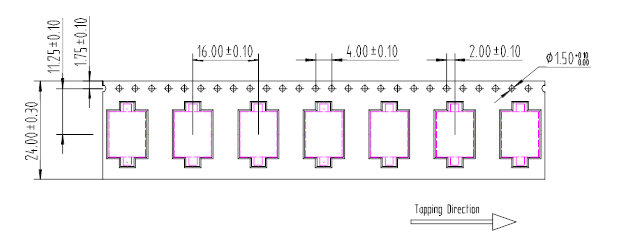

2. Dimensions Unit: mm

*Housing Material: Black LCP

*Terminal plate: 2 soldering pads, gold Plating Brass

| 3. Electrical And Acoustical Measuring Condition |

Recommended Setting

|

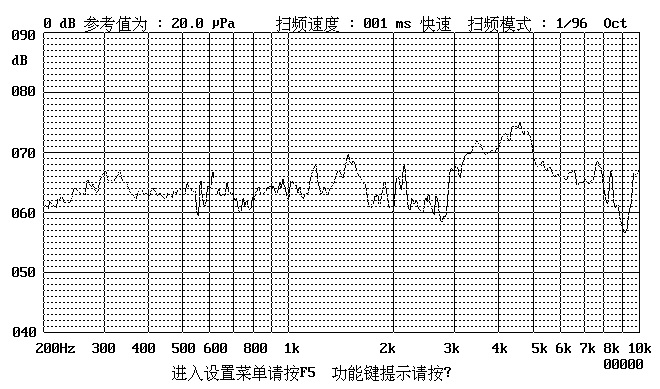

4.Frequency Response

5.Reliability Test

a)Ordinary Temperature Life Test

The part shall be subjected to 96 hours at 25±10℃. Input rated voltage Resonant frequency, 1/2 duty Square wave.

B )High Temperature Test

The part shall be capable of with standing a storage temperature of +85℃ for 96 hours.

c)Low Temperature Test

The part shall be capable of with standing a storage temperature of -40℃ for 96 hours.

d)Humidity Test

Temperature:+40℃±3℃ Relative Humidity:90%~95% Duration: 48 hours and expose to room temperature for 6 hours

e)Temperature Shock Test

Temperature:60℃ /1hour→ 25℃/3hours→-20℃/1hour→ 25℃/3hours (1cycle)

Total cycle: 10 cycles

f)Drop Test

Standard Packaging From 75cm(Drop on hard wood or board of 5cm thick, three sides, six plain.)

g)Vibration Test

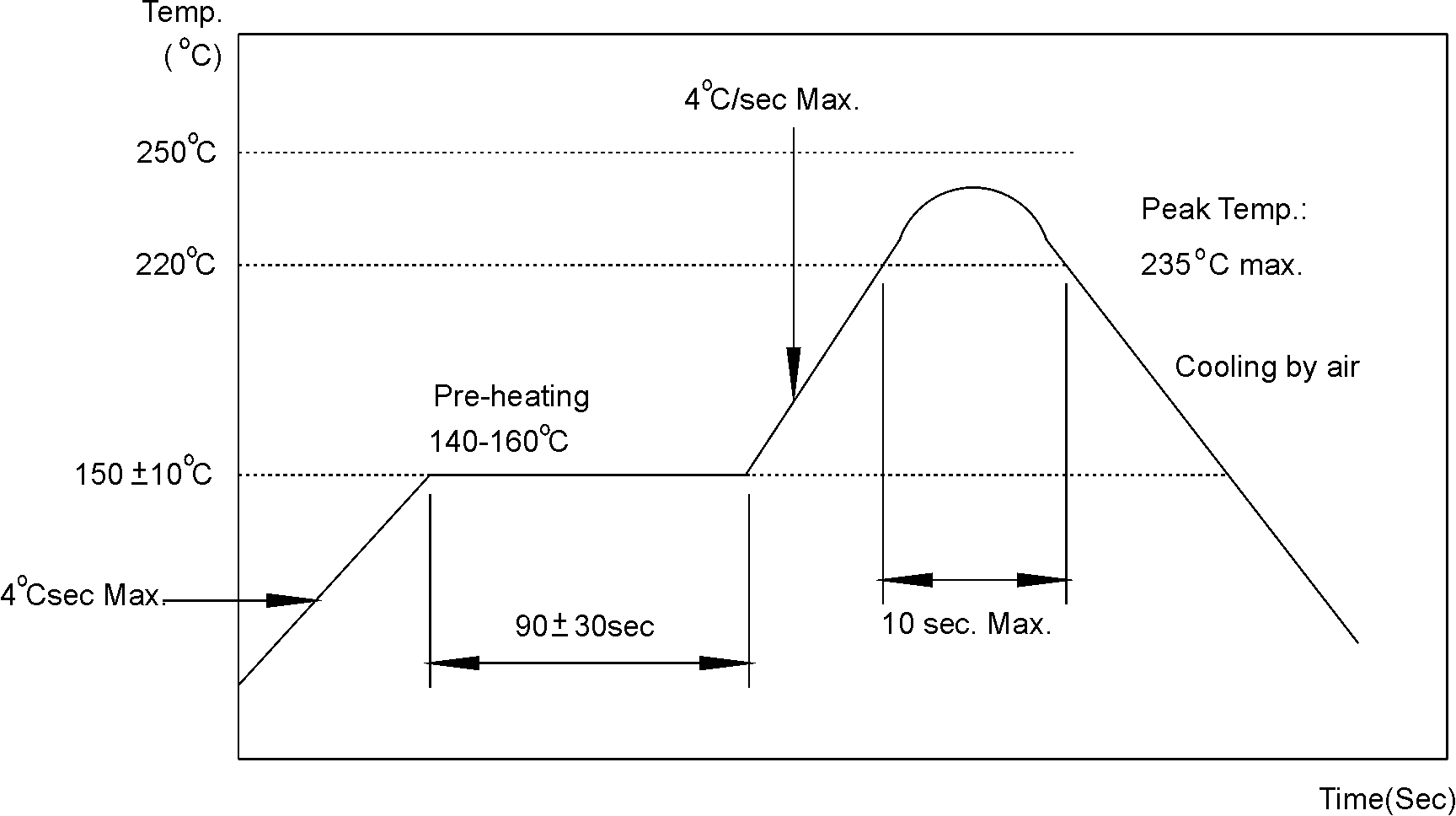

h)7.8Reflow Test

(1) No abnormality should be found after reflow

(2) Good soldering to meet soldering requirements

Note:

As this product is not protected from foreign material entering, please make sure that any foreign materials (e.g. magnetic powder, washing solvent, flux, corrosive gas) do not enter this product in your production processes. The functional degradation (e.g. SPL down) may occur if foreign material enter it.

6. Surface mounting condition

6.1 Reflow soldering

Recommendable reflow soldering condition is as follows.

Note: (1) In automated mounting of the SMD sound transducers on PCB, any bending, expanding

and pulling forces or shocks against the SMD sound transducers shall be kept minimum

to prevent them from electrical failures and mechanical damages of the devices.

(2) In the reflow soldering, too high soldering temperatures and too large temperature

Gradient such as rapid heating or cooling may cause electrical failures and mechanical

damages of the devices.

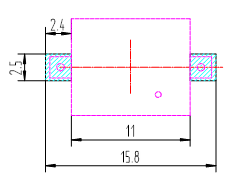

6.2 Soldering pattern

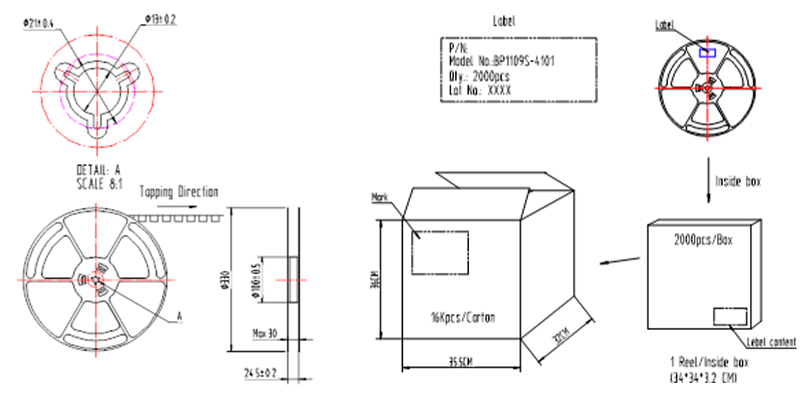

7.Packing

Packaging Requirements |

Tape Packaging: for details, please refer to the drawing requirements outer box item number: F6-005; Outer box size 35*32 * 36cm inner box item number: F6-054; Inner box size 76 * 45.5cm carrier tape item number: F6-S11091 Each carrier plate is packed in a large PE bag and then put into the inner box; PE bag item number: F6-607 |

|

shipping mark requirements |

inner box: according to customer order |

carton: according to customer order |

Keywords: Buzzer BP1109S

上一个:

: 下一个

上一个:

下一个:

询价

欢迎给我们留言,我们会尽快与您联系!